This post is a companion post to my YouTube video on how to enable anti-cogging on your ODrive robotics High Performance Motor controller. You can find the source coee from the video below. Note these are based on my settings from the ODrive D5065 Motor so your settings will vary from mine. Quick disclaimer: We…

Category: Electronics

Arduino RC Controller Input – Part 1

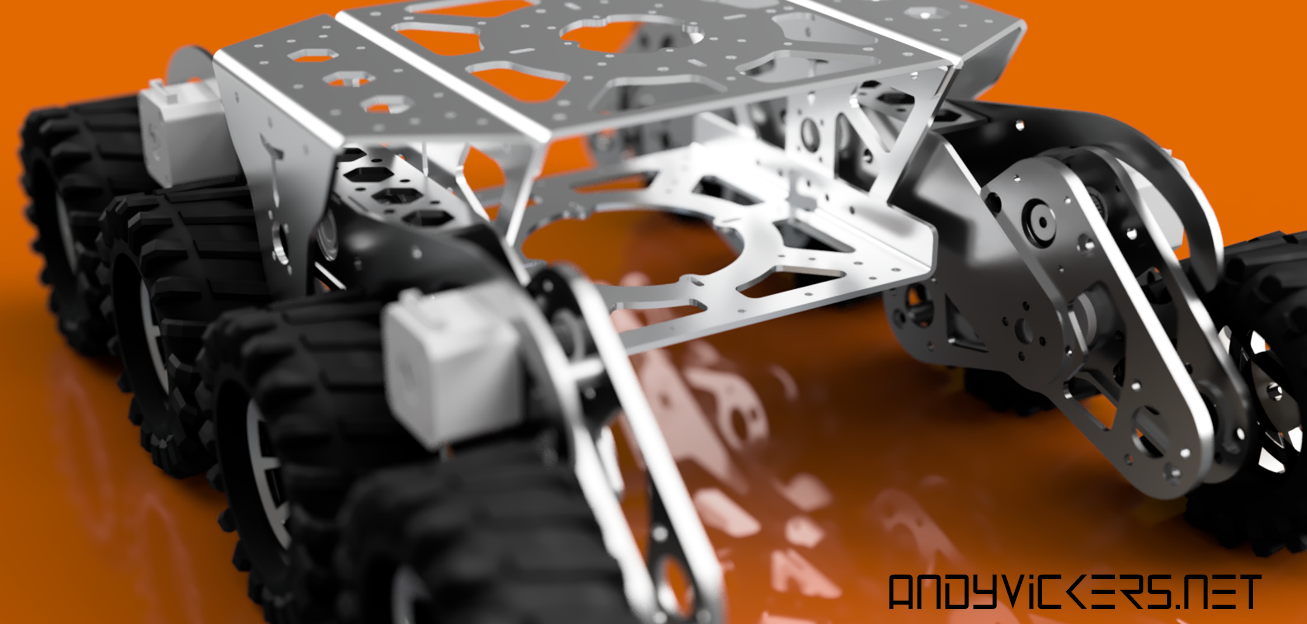

As I continue to build my robot, one of the important elements is having a controller that I can use to manually move and test the motors. There are a few examples of projects others have done that make controllers that are Arduino or pi based for example James Bruton’s smart robot remote below Building…