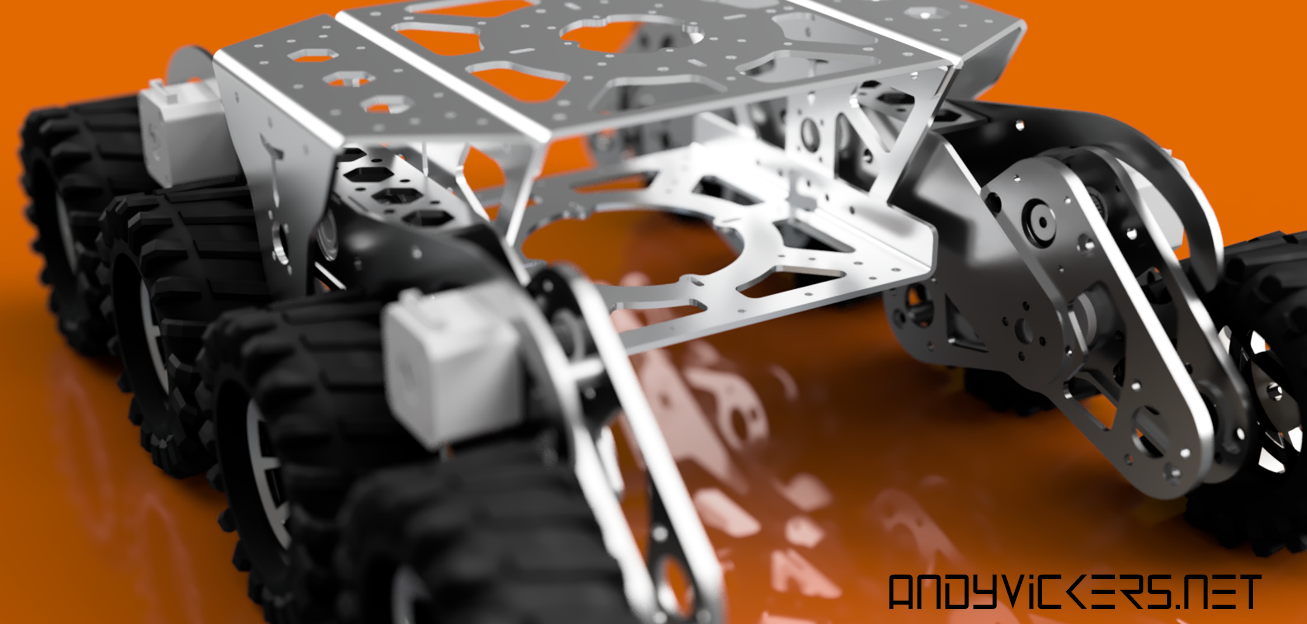

Its high time my suspension and my wheels got connected to a chassis . We need a place to house all the electronics and general payload of the robot . I used Fusion360 to put together some rough designs that used 2020 extrusions and milled plates to build a chassis. The basic layout so far…

andyvickers.net

My Adventures with Technology