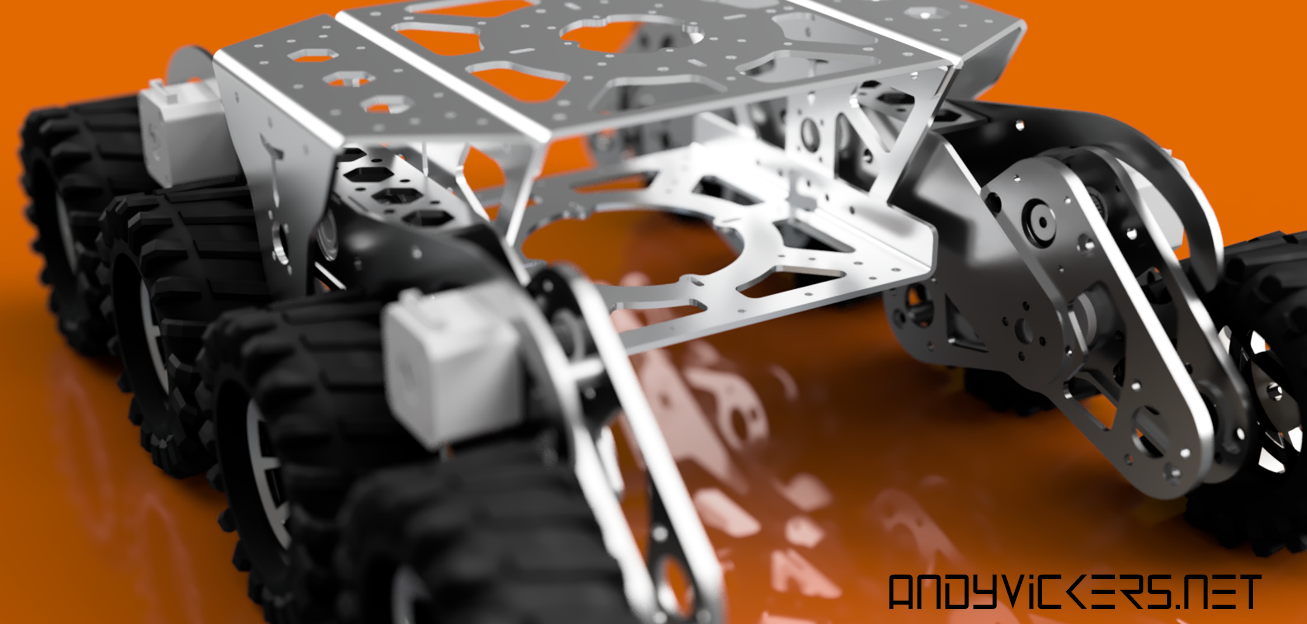

</puns> So starting from where we left off last time, as I said I pretty much designed the chassis around 2.2″ RC wheels with some nice big 120mm tires. That gives me a lot of bounce in just the rubber for absorbing some of the shock of moving around. They also are easily available and…

Tag: Jarvis

Jarvis – Revisited

There’s something about this COVD crisis that makes me want to dust off old projects, old hobbies and pick up where I left off. I wonder how we will look back on this in years to come. Will we think that the stay at home measures were excessive? or will we think that our actions…